All of our Cryo-Processing is preformed in machines designed and manufactured by Applied Cryogenics, Inc. in Burlington, MA.

ACI is led Dr. Jeff Levine is the sole producer of vacuum insulated Cryoprocessors. Dr. Levine holds both B.S. and Ph.D. degrees in physics from the Massachusetts Institute of Technology. He draws on and extensive background in experimental physics in designing these unique devices. Based on our long track record of consistently outstanding results achieved with ACI Cryoprocessors we are proud to be a distributor of these machines.

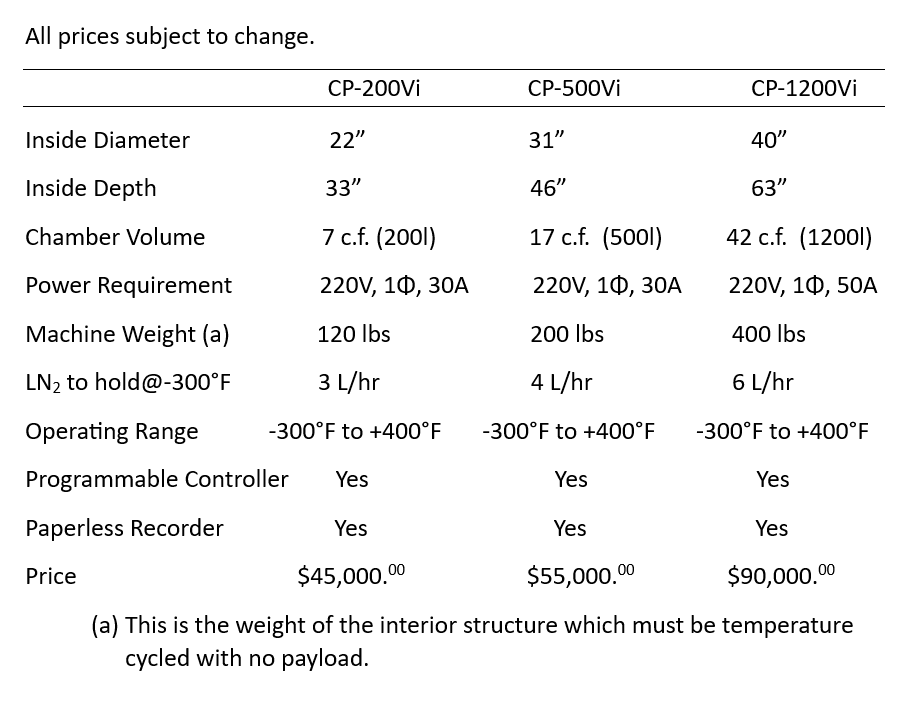

Three standard sizes are offered; custom modifications are possible. All operate between the temperature limits of -300 °F. And +400 °F. Tempering of refrigerated parts can be done without the need for a separate oven. Rates of temperature change and dwell times are determined by an industrial programmable controller. A permanent record of each run is displayed and preserved by a paperless recorder. Set point temperature, chamber temperature, and Material temperature are monitored. An internal heat exchanger ensures that cooling is via the gas kinetic transfer of heat. Liquid Nitrogen does not contact the payload. The use of vacuum insulation minimizes heat gain from the external environment; hence, LN2 is minimized. (1)

Two ACI CP-1200vi Cryoprocessors installed at a major consumer products company

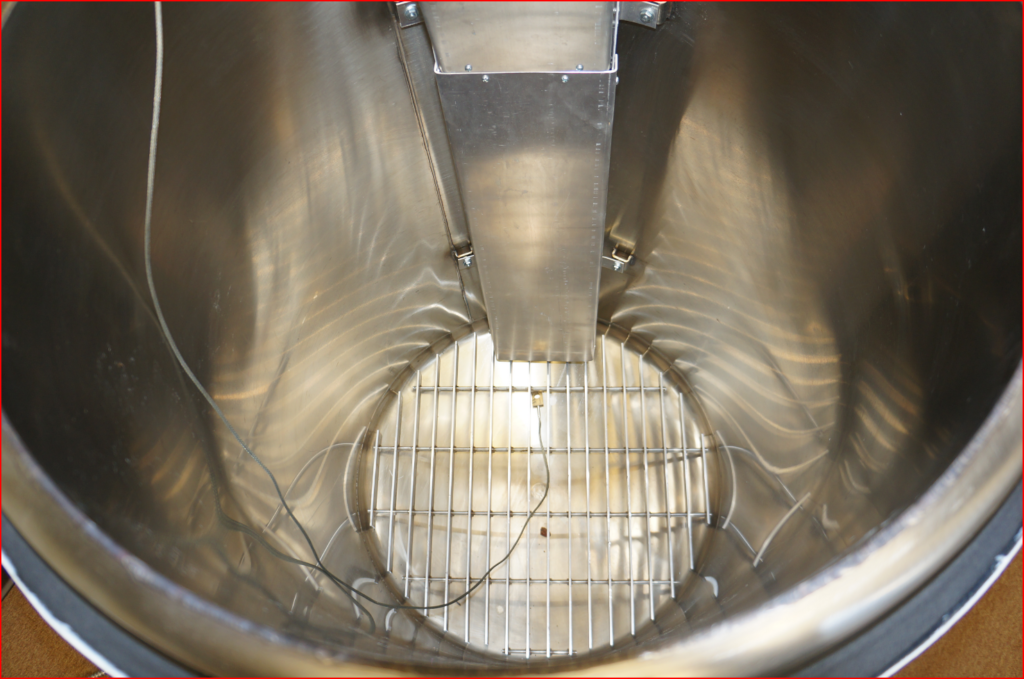

Interior view of the CP-200vi cryoprocessor vacuum insulated chamber.

The ACI CP-200vi cryoprocessor.